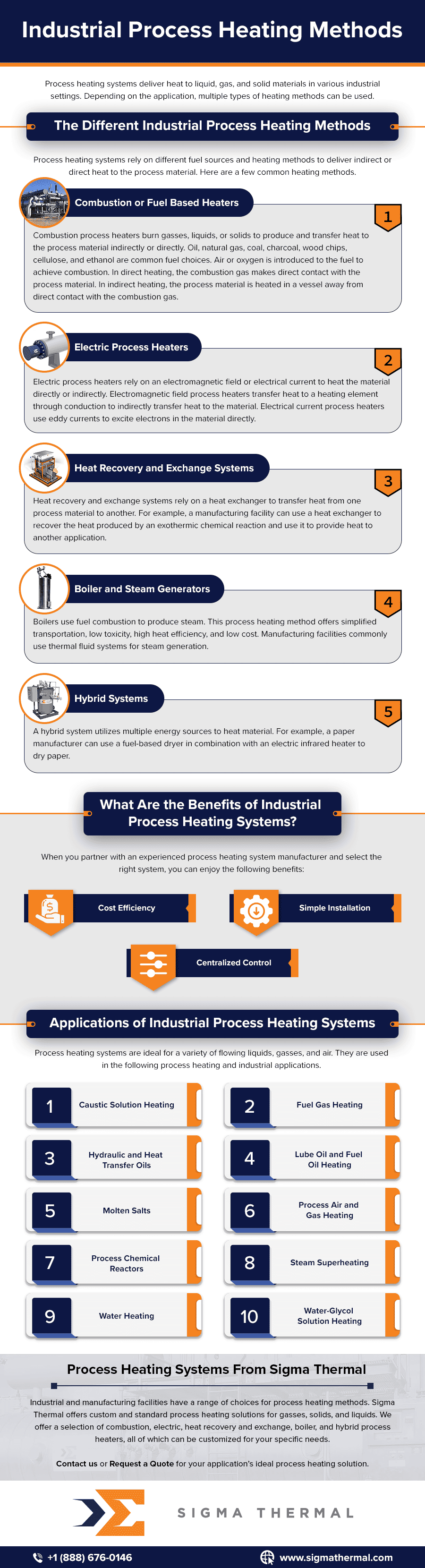

Industrial process heating systems supply heat to liquids, gases, and solid materials across a variety of industrial settings. Depending on the application, numerous heating methods can be employed. We’ll delve into several of these industrial heating methods along with their advantages and applications to help you identify the perfect solution for your needs. Process heating systems depend on different fuel sources and heating methods to deliver either indirect or direct heat to the process material. Here are some common heating techniques. Combustion process heaters burn gases, liquids, or solids to generate and transfer heat to the process material either directly or indirectly. Common fuel options include oil, natural gas, coal, charcoal, wood chips, cellulose, and ethanol. Air or oxygen is introduced to the fuel to enable combustion. In direct heating, the combustion gas comes into direct contact with the process material. In contrast, indirect heating heats the process material inside a vessel without direct contact with the combustion gas. Electric process heaters work by passing an electric current through resistive heating elements to produce heat. These heating elements can then be used to directly or indirectly heat processes in tanks, ducts, or circulation vessels. Heat recovery and exchange systems rely on a heat exchanger to transfer heat between different process materials. For instance, a manufacturing plant might use a heat exchanger to reclaim heat from an exothermic chemical reaction and utilize it to warm another application. Boilers use fuel combustion to create steam. This heating method offers easy transport, low toxicity, high heat efficiency, and affordability. Boilers are among the most popular process heating solutions in manufacturing facilities. However, they can be complex and require careful consideration of various factors to ensure efficiency and performance. Thermal fluid heating systems employ a heat transfer medium in its liquid state that circulates through the heater and reaches the heat transfer consumers. These systems often use organic or synthetic oils, enabling them to operate at high temperatures with minimal or no pressure compared to boilers. A hybrid system combines multiple energy sources to heat materials. For example, a paper manufacturer might use a fuel-based dryer combined with an electric infrared heater to dry paper efficiently. Partnering with an experienced process heating system manufacturer and selecting the right system can yield the following benefits: Process heating systems are ideal for heating flowing liquids, gases, and air in various industrial processes. They are utilized in the following applications: Industrial and manufacturing facilities have many options when it comes to process heating methods. Various types of heating systems are available for solid, liquid, and gas materials, with both direct and indirect heating options. Partnering with a knowledgeable and capable provider is crucial to selecting the ideal process heating system for your application, ensuring optimal performance and efficiency. Sigma Thermal offers custom and standard process heating solutions for gases, solids, and liquids. Our selection includes combustion, electric, heat recovery and exchange, boiler, and hybrid process heaters, all of which can be tailored to meet your specific requirements. Sigma Thermal is ISO 9001:2015 certified and serves a global market. Contact us or request a quote for the best process heating solution for your application.    EPS cutting machine,EPS foam cut machine,Eps Styrofoam Machine Foam Cutting Machine Hangzhou Sutuan Machinery Co.,Ltd.Industrial Process Heating Techniques

Different Types of Industrial Process Heating Techniques

Combustion or Fuel-Based Heaters

Electric Process Heaters

Heat Recovery and Exchange Systems

Boilers and Thermal Fluid Heating Systems

Hybrid Systems

Advantages of Industrial Process Heating Systems

Applications of Industrial Process Heating Systems

Process Heating Solutions From Sigma Thermal

Leading EPS EPP ETPU machinery manufacturer , https://www.sutuanmachinery.com

Industrial Process Heating Methods

Click to Expand