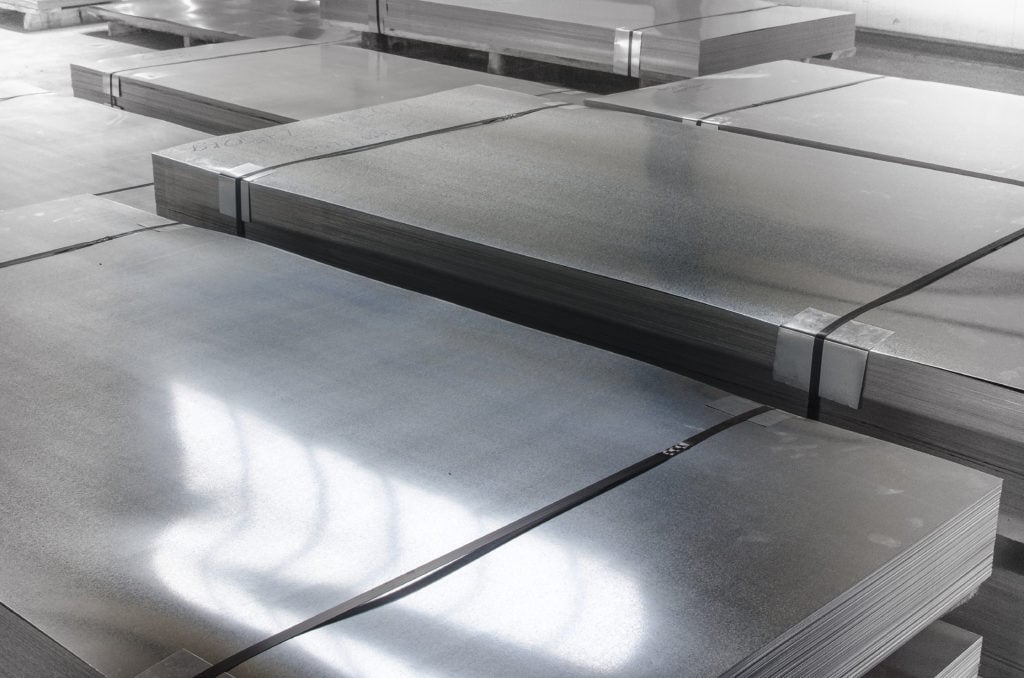

Throughout 2021, the global market has experienced a sharp rise in the prices of key metals such as steel, stainless steel, copper, and others. These fluctuations have created challenges for manufacturers and businesses alike. However, ESI has developed strategies to navigate these price swings, ensuring that our customers continue to receive high-quality, cost-effective metal solutions. Our deep knowledge of various metals has given us valuable insight into how volatile pricing can impact overall business costs. This experience allows us to provide better guidance and support to our clients as they plan and execute their projects. According to a recent article in the New York Times, steel, stainless steel, aluminum, and copper are at record highs. Three main factors are driving this increase during the post-pandemic recovery: The U.S. has been implementing tariffs to reduce reliance on imported materials, which has already started pushing up prices. Companies are being encouraged to consolidate and bring manufacturing back home. For example, aluminum importers face supply constraints from Canada, while demand for copper and nickel is surging due to growth in energy storage and electric vehicles (EVs). This trend also creates new job opportunities across the U.S. economy. This reshoring movement accelerated during the pandemic, and even with ongoing shipping issues and truck driver shortages, some tariffs remain in place, further increasing costs. Supply chain problems worsened throughout the pandemic, leading to raw material shortages as companies ramp up production. As a result, freight shipping costs have reached all-time highs. Reports show that China’s top 10 ports saw an average 126% increase in D&D charges compared to the previous year. These issues aren’t limited to international trade. The shortage of truck drivers, exacerbated by the pandemic and the rise of e-commerce, has led to longer lead times. Some industry experts have even called it a “shipping Armageddon.†These trends have led to a situation where demand for materials outpaces supply, making it difficult for manufacturers to secure pricing and lead times for projects. As industries adapt to these challenges and scale up production during the post-pandemic recovery, the demand for metal products is expected to grow. When combined with the push for clean technology, renewable energy, and infrastructure development in the U.S. and China, this creates a perfect storm for sustained high metal prices. While supply issues and high demand are impacting nearly every metal market, the most commonly used industrial metals are seeing the biggest price increases. Manufacturers should expect higher costs for steel, aluminum, copper, and nickel. How to Select the Right Material for Your Stamped Metal Part: Learn more here Although metal prices are expected to decline as the global economy recovers, they are unlikely to return to pre-pandemic levels soon. With large-scale infrastructure projects in the U.S. and China still driving demand, the market may stay tight through 2022. Additionally, ongoing shipping challenges could extend lead times for certain materials. To stay ahead, we recommend planning for extended timelines when sourcing materials in 2022. With sourcing uncertainties and project delays becoming more common, it's essential to understand how material choices affect both cost and delivery time. At ESI, we help you make informed decisions to keep your projects on track and within budget. We are proactively securing materials for future projects, leveraging our 30-year relationships with metal suppliers. Our team provides insights into alternative designs and materials that can improve cost efficiency or speed up delivery without compromising performance. No matter what the market looks like, ESI remains committed to offering competitive pricing. We closely monitor metal prices and trends to ensure your project is completed efficiently and economically. Contact us today to learn more about our metal products and services. {

"@context": "https://schema.org",

"@type": "FAQPage",

"mainEntity": [{

"@type": "Question",

"name": "When Will Metal Prices Drop and Lead Times Stabilize?",

"acceptedAnswer": {

"@type": "Answer",

"text": "Over the course of 2021, the market has seen prices for steel, stainless steel, copper, and other popular base metals rise significantly. Fortunately, ESI has learned how to work with market fluctuations to create sustainable, cost-effective metal products for our customers. Our extensive experience working with a variety of metals also gave us an inside look at the effects that fluctuating metal prices can have on the overall cost of business operations."

}

},{

"@type": "Question",

"name": "Why is the price of metal increasing?",

"acceptedAnswer": {

"@type": "Answer",

"text": "According to a recent article published in the New York Times, prices for steel, stainless steel, aluminum, and copper are at record highs. There are three primary reasons for the price increase in our post-COVID economic recovery period."

}

},{

"@type": "Question",

"name": "Which metals are affected?",

"acceptedAnswer": {

"@type": "Answer",

"text": "While supply shortages and high demand are affecting almost every metal market, the metals most frequently used in industrial production are the most affected. Manufacturers can expect to see increases in steel, aluminum, copper, and nickel especially."

}

}]

} Solvent Based Printing Ink For Glass,Solvent Based Ink,Solvent Based Ink For Screen Printing,Solvent Based Ink For Glass Sheet Lauer Water-Based New Material(Foshan)Co.,Ltd. , https://www.lauerink.com

Why Are Metal Prices Rising?

1. Tariffs and Reshoring Efforts

2. Pandemic-Related Transportation Disruptions

3. Global Supply Constraints

Which Metals Are Most Affected?

When Will Prices Drop?

Stay Competitive with Cost-Efficient Metal Products from ESI

A Glass Roller Coater is an essential tool for applying glass ink to glass surfaces. The machine applies ink accurately and consistently, ensuring high quality and uniformity of printed designs on glassware. The machine works by using a roller to evenly distribute ink onto the glass surface, resulting in a smooth and professional finish.

When Will Metal Prices Drop and Lead Times Stabilize?

Glass Ink is a special type of ink formulated to adhere to glass surfaces and withstand the various stresses that glassware may be subjected to, such as cleaning and handling. It usually consists of pigments, solvents and additives that allow it to bond to glass and form a durable and long-lasting print.

The solvent-based nature of glass ink means it dries quickly and forms a strong bond with the glass surface. This makes it ideal for use in industrial environments where rapid production is required. Additionally, glass ink's vibrant colors and high opacity make it a popular choice for creating eye-catching designs on glassware.

Comments are closed