An internal inspection is a process used to examine the inside of an asset or structure. It plays a vital role in ensuring that all parts of the equipment are safe, functional, and free from damage. Alongside external inspections, internal inspections provide a complete picture of an asset’s condition. Internal inspections are sometimes referred to as interior or inner inspections. These assessments help identify any internal defects, wear, or structural issues that may not be visible from the outside. They are essential for maintaining the integrity and safety of industrial equipment and infrastructure. Historically, internal inspections were conducted manually by sending inspectors into confined spaces such as tanks, boilers, or pipelines. This method was both time-consuming and risky. However, with advancements in technology, modern solutions like drones and robotics have revolutionized the way these inspections are performed. For example, Flyability’s indoor drones allow inspectors to stay safely outside while collecting high-quality visual data from within the asset. Inspectors perform internal visual inspections to ensure assets remain in good working order. In some cases, they may also use non-destructive testing (NDT) methods to gather more detailed information during the inspection. NDT allows for thorough evaluation without damaging the asset, making it ideal for ongoing maintenance and safety checks. [Internal inspections are just one area in which inspectors use non-destructive (NDT) testing methods. Learn more about NDT and the other scenarios in which it is performed in this guide.] There are several methods used to conduct internal inspections, each with its own advantages and limitations. The most common approaches include: The goal of each method is to enable inspectors to collect accurate data about the internal condition of an asset. Depending on the situation, these methods can be used individually or combined to achieve the best results. With scaffolding and rope access, inspectors physically enter the space to inspect the interior. In contrast, RVI tools—such as drones or robotic systems—allow inspectors to remain outside while gathering visual data remotely. Scaffolding is a temporary structure built to support inspectors as they move around inside large or complex assets. While this method has been widely used, it is often expensive and time-consuming due to the need for setup, dismantling, and asset downtime. Despite its cost, scaffolding has long been the standard for internal inspections. However, many companies are now exploring alternative methods to reduce costs and improve efficiency. Learn more about scaffolding and all its uses in our in-depth guide. Internal rope access is a specialized technique used to reach difficult or high places within an asset. Certified technicians use ropes and safety gear to perform inspections inside structures like pressure vessels, chimneys, and storage tanks. This method offers greater flexibility than scaffolding and is often faster and less disruptive. However, it requires highly trained professionals to ensure safety and accuracy. Learn more about rope access in our in-depth guide. Using remote visual inspection (RVI) tools like drones or robots has become increasingly popular. These tools allow inspectors to gather visual data without entering dangerous or confined spaces, improving safety and reducing downtime. Drones like Flyability’s Elios 3 can navigate tight spaces and capture high-resolution images and video. This makes them ideal for inspecting pipelines, sewers, and other hard-to-reach areas. By using RVI tools, companies can save time, reduce costs, and improve safety. Additionally, these tools can help lower insurance premiums by minimizing the need for human entry into hazardous environments. Learn more about inspection tools in our in-depth guide. During an internal inspection, inspectors typically focus on answering three key questions using non-destructive testing (NDT) methods: The first step in any internal inspection is to identify whether any defects exist. Inspectors document these findings and maintain a historical record of the asset’s condition over time. Locating defects can be challenging, especially when using remote tools like drones. Without GPS or clear reference points, it can be difficult to pinpoint exactly where a defect is located. Some inspectors use barometric measurements, blueprints, or software tools to track the position of defects in real-time. Flyability’s Inspector 3.0 software, for instance, provides a sparse point cloud that helps inspectors visualize and share defect locations with other stakeholders, such as engineers or maintenance teams. Knowing the size and extent of a defect is crucial for determining the next steps in maintenance or repair. It helps teams decide whether further inspection, monitoring, or immediate action is needed. Internal inspections are critical across various industries, particularly in sectors where equipment failure could lead to serious consequences. Even small defects can escalate into major safety hazards if left unchecked. Here are the industries where internal inspections are commonly performed: Common assets that require internal inspections include: condensator and evaporator condensator of car Xinxiang Yukun Refrigeration Technology Co.Ltd , https://www.yukunevaporator.comWhat Is an Internal Inspection?

Ways To Conduct An Interior Inspection

Scaffolding

Internal Rope Access

Remote Visual Inspection Tools

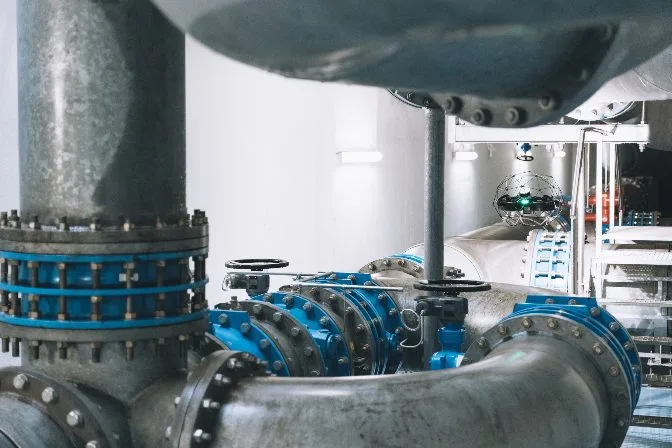

The Elios 3 performing an inspection at a water department

The Elios 3 performing an inspection at a water departmentThree Questions Inspectors Must Answer When Conducting Internal Inspections

1. Are there any defect(s) in the asset?

2. Where are the defect(s) located?

3. What are the dimensions of the defect(s)?

Industries & Assets That Require Internal Inspections