Buying a robot for the first time or even if you've done it before, selecting the right robotic system integrator is crucial for your next robotics project. But how do you know what to look for in a robotic system integrator? Let's break it down. A top-notch robotic system integrator plays a vital role in streamlining your operations. They assess your facility's requirements, design a tailored automation strategy, and implement a solution that boosts your production efficiency. By doing so, they help reduce costs while maximizing productivity. Whether it's assembly, packaging, or welding, a skilled integrator can automate a wide range of tasks to meet your specific needs. 1. Experience and Credibility Matter. Not all robotic system integrators are created equal. Some may specialize in small-scale projects, while others handle large-scale implementations. It's important to choose an integrator with proven experience working with businesses similar to yours. Discuss your operational challenges and ask for case studies or testimonials showcasing their past successes. 2. Quality Solutions Are Essential. A reliable integrator will conduct a thorough analysis of your existing workflows. They'll identify bottlenecks and suggest innovative ways to enhance efficiency. For instance, they could recommend advanced sensors or software tools to optimize performance. 3. A Customized Automation Plan Is Key. The right integrator will craft a comprehensive automation plan that aligns with your budget, compliance requirements, and safety standards. This plan should include strategies to minimize downtime and ensure smooth operations. Additionally, they should outline steps to maintain 24/7 functionality, which is critical for continuous production. 4. Execution Matters. A great plan is only as good as its execution. Your chosen integrator should have the technical expertise to bring your vision to life. This involves rigorous testing, fine-tuning the system, and providing hands-on training for your team. Post-installation, they should address any issues promptly and ensure everything runs smoothly. 5. Ongoing Support Is Non-Negotiable. Even after the initial setup, you'll need reliable support. Look for an integrator that offers round-the-clock assistance, especially if you operate across multiple locations. A global network ensures timely service whenever you need it. With Genesis Systems, enjoy seamless support anytime, anywhere. Our 24/7 customer service ensures your operations run without a hitch. Remember, investing in the right robotic system integrator isn't just about saving money—it's about achieving long-term success. Take the time to evaluate potential partners carefully, and you'll reap the rewards for years to come. rubber repair,repair strip,conveyor belt repair strip,conveyor belt rubber repair,patch Hebi Shuanglian Trading Co., Ltd. , https://www.slwearrubber.comWhat to Look For in a Robotic System Integrator

Why You Need a Robotic System Integrator

Key Considerations When Choosing a Robotic System Integrator

What To Look For in A Robotic System Integrator

# What to Look For in a Robotic System Integrator

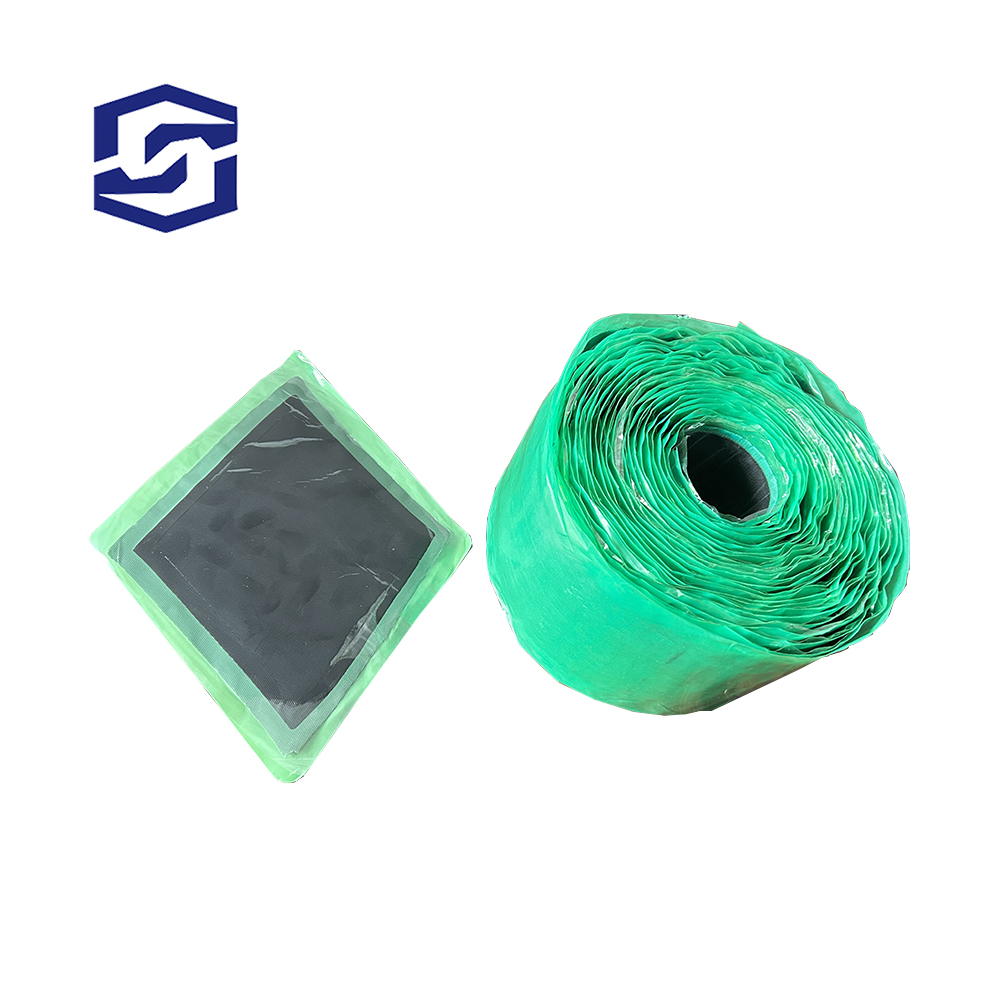

SL rubber repair series products are widely used, mainly used for rubber products and polyurethane and other elastomer damage repair.

Â

Such as: repair of various damage of conveyor belt, repair of wear resistant pipe lining damage, sealing of conveyor belt joints, cold patching of cables, coating of turbine blades, protection of belt buckles, and other kinds of rubber products.

Â