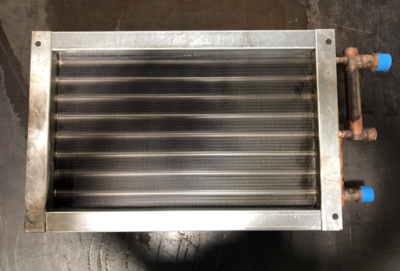

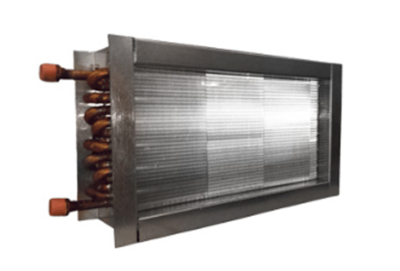

As the colder season approaches, replacing hot water coils becomes increasingly common. A high-quality replacement hot water coil is an economical solution that ensures optimal performance while maintaining efficiency... THE INNER WORKINGS OF A HOT WATER COIL Hot water coils function as tube-fin heat exchangers, featuring rows of tubes that pass through sheets of formed fins, securely bonded via tube expansion. As cool air flows over the coil and makes contact with the heated fin surface, heat transfers from the warm water circulating within the tubes to the incoming cold air, enabling efficient heat exchange to take place. These hot water coils serve a variety of purposes, such as energy recovery, reheating, preheating, booster heating, and providing comfort heating. DESIGN VARIATIONS IN HOT WATER COILS While all hot water coils share similar characteristics, their materials of construction and design specifications vary depending on the intended application. Typically, they comprise 1 to 3 rows of tubes, though some may have more. The standard materials include copper tubes paired with aluminum fins, with copper tubes available in 5/8", 1/2", or 3/8" diameters. Water can flow through the coil's tubes at temperatures reaching up to 200˚F. In highly corrosive settings or food processing environments, coils may be crafted using stainless steel tubes or fins instead. A hot water coil can be manufactured with or without headers. Without a header, it might be called a booster coil, reheat coil, or even a heater core coil. The primary role of a booster coil is to restore warmth to air that has cooled during its journey through ductwork, particularly in areas distant from the air handler. Occasionally, the coil may feature a collection header on the opposite side, a configuration often encountered when replacing Heatcraft™/McQuay® hot water coils. Over time, we've fabricated numerous custom and OEM replacement hot water coils—ranging in size from a simple picture frame to the dimensions of a wall—and many of these serve as reliable substitutes for Carrier®, Trane®, York®, and other leading brands. SIZING YOUR HOT WATER COIL Replacing hot water coils is relatively straightforward when it comes to achieving precise fit and performance. For a replacement coil, we measure the fin height, fin length, and count the number of rows wide. When designing a new hot water coil, we require the CFM (face velocity for hot water coils can reach up to 1250 ft/m), entering dry bulb temperature, GPM (if applicable), and the desired capacity/leaving air temperature. If you're measuring your own coil, check out our blank coil drawings page to ensure accurate recording of construction details and sizing. EASY ORDERING OF HOT WATER COILS Nationwide Coils offers a range of custom options for your hot water coil needs, along with select stock sizes to meet all your commercial and industrial heating requirements. For any questions or quotes regarding hot water coils or other replacement/custom coils, feel free to contact us via email. Our team at Nationwide Coils is dedicated to simplifying your work process. If you're in the automotive repair business, you definitely want to ensure your clients are getting perfect wheel alignments. YuanMech premium Wheel Aligners consistently set the industry standard for accuracy, speed and simplicity of use. YuanMech 3D Wheel Aligners are capable of accurately determining angles and calculations to a high degree of precision. Wheel Aligner,Wheel Aligner Machine,3D Wheel Alignment Machine,Automatic Track Wheel Aligner Yingkou Yuanmech Machinery Co Ltd , https://www.yuanmech.comA Closer Examination of Replacement Hot Water Coils – But Not Too Close, They're Scorching!

Written by: Andre Ostacoli

Nationwide Coils, Inside Sales Manager