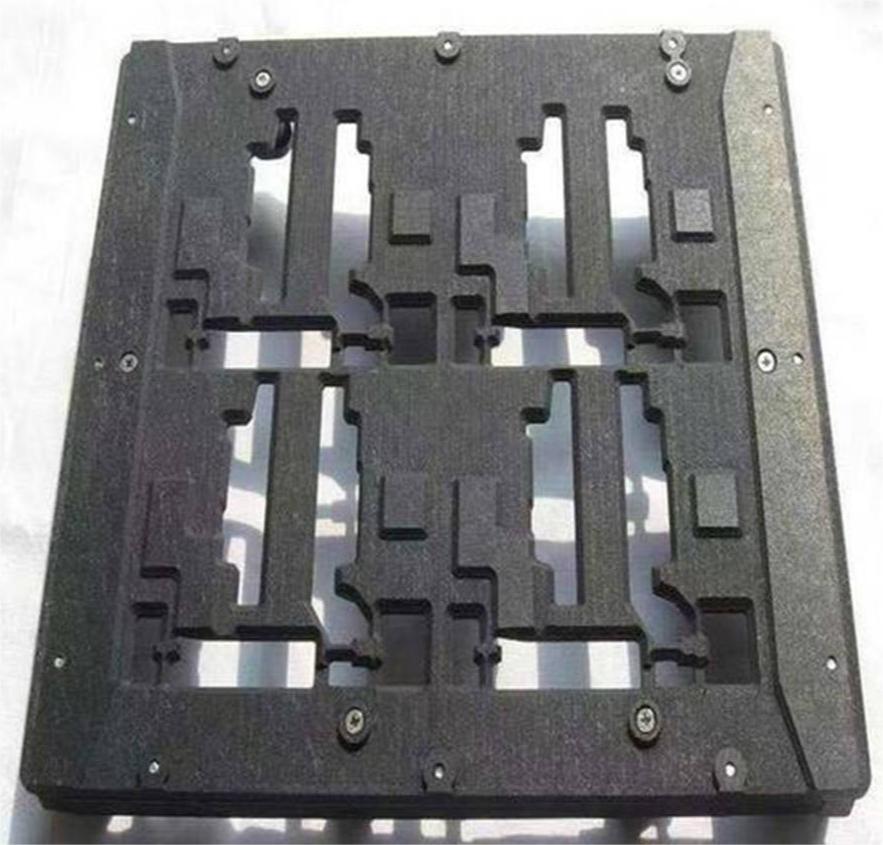

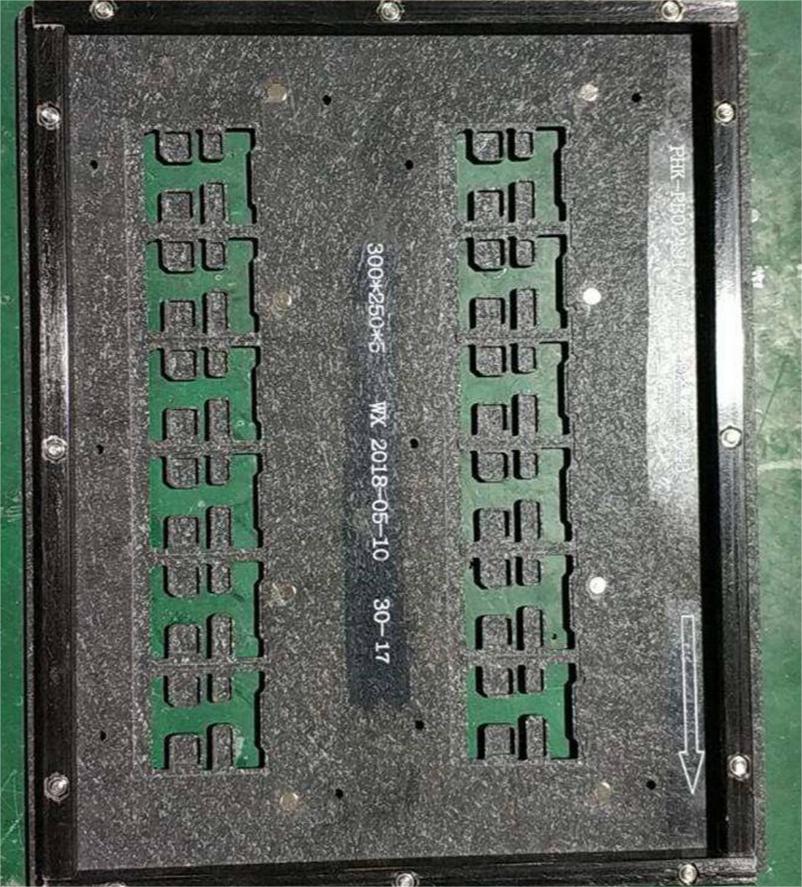

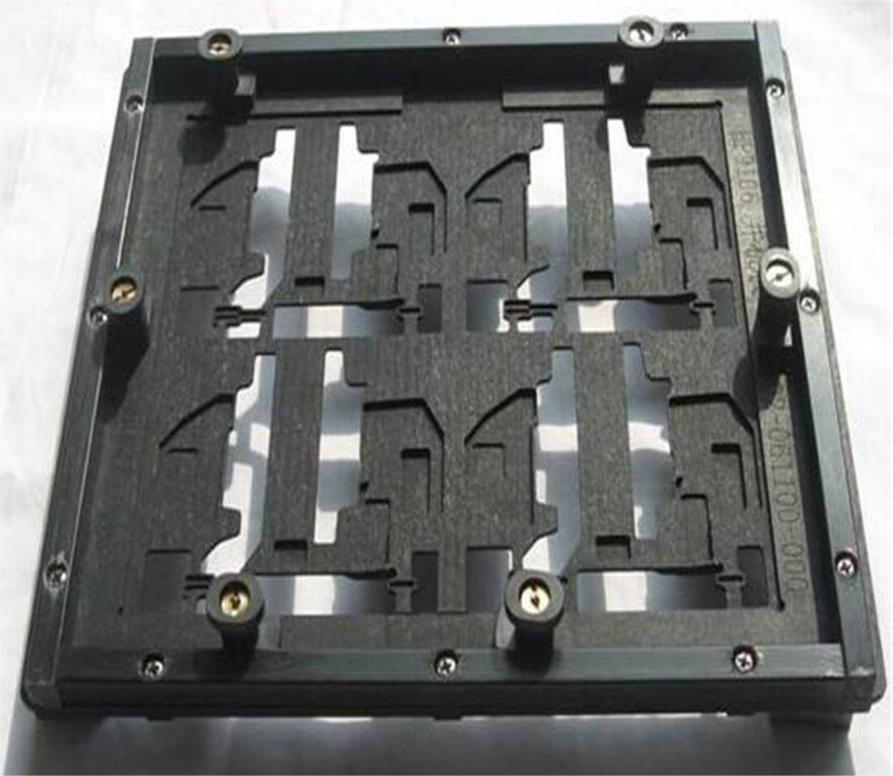

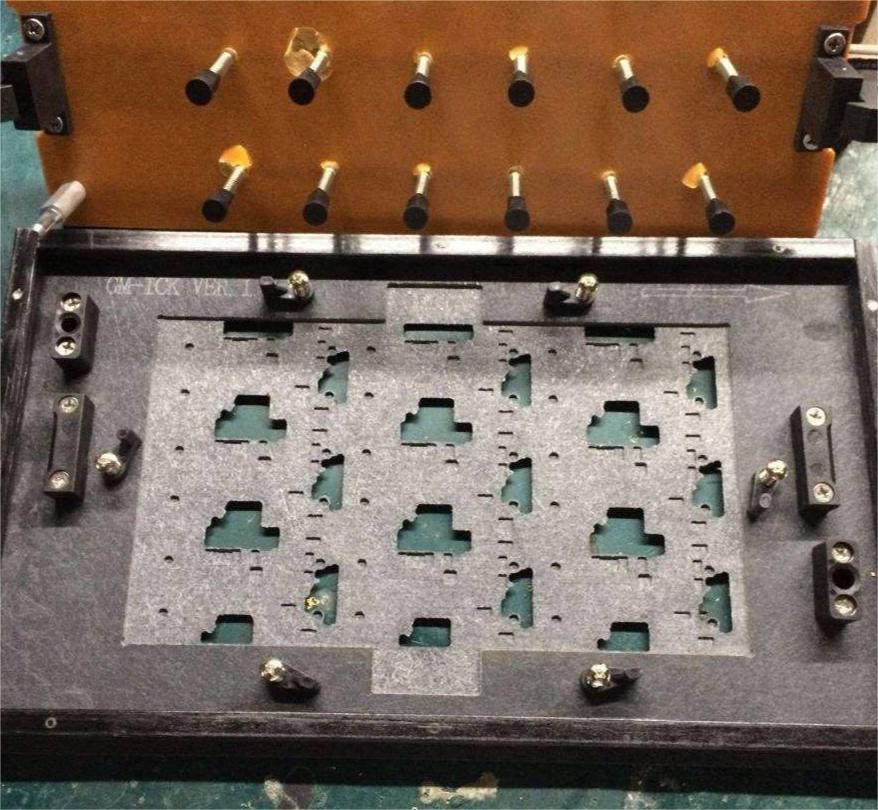

The heavy-duty glass fibre reinforced plastic Durostone®and Glastic® offer extreme strength and excellent electrical, thermal and chemical properties. Durostone® pressed sheets meet the requirements of the EN 60893 standard. Durostone® and Glastic® are manufactured by using Wave Solder Pallet durostone range: The product range comprises sheets, composite profiles, wound components, compression molded parts and finished components of almost any type and size (up to 4 m [13.13 ft.] by 2.8 m [9.19 ft.]) for these applications. Welding Pcb Reflow Solder Pallet Applications: Durostone® and Glastic® are especially well-suited for the use in generator construction, switchgear, chemicals processing equipment and transportation systems. Durostone® materials have been developed for all procedures within the PCB assembly process. There are three main grades which are suitable for use in the SMT reflow and wave soldering processes Durostone® is Produced in Three Standard Grades: CHP 760 (Blue) (Standard) CAS 761 (Black) (Anti-Static) CAG 762 (Grey) (Anti-Static, Optical) Antistatic durostone offer the following features: Excellent mechanical properties at elevated temperatures including the lead-free process.Low thermal conductivity.Excellent machining properties enabling the manufacture of complex design solder pallets.Good resistance to chemicals used in modern fluxes. FEATURES AND BENEFITS of Durostone® Wave Solder Pallet Material All materials are dimensionally stable and retain their flatness through repeated cycling in the PCB assembly process. The low thermal conductivity of Durostone® ensures optimal thermal distribution across the PCB. The resin system used in Durostone provides resistance to the chemicals used in fluxes and also prevents solder pick-up. Can be machined to tight tolerances. Wave Solder Pallet durostone,Durostone®Glastic® Fibre reinforced materials,durostone CHP760 CAS761 CAS762,Welding Pcb Reflow Solder Pallet,Antistatic durostone,durostone Hony Engineering Plastics Limited , https://www.honyplastic.com

**Specifications:**

45/90, 45/100, 50/105, 51/105, 55/110, 55/120, 58/124, 60/125, 65/120, 65/132, 68/143, 70/140, 75/150, 80/143, 80/156, 92/188

**Screw Diameter:** Ø 20mm - Ø 220mm

**Mold Clamping Force:** 250T - 3200T

**Shot Weight:** 30g - 30,000g

**Technical Information**

**Base Materials:**

(1) 38CrMoAlA (JIS SACM645)

(2) 42CrMo (AISI 4140)

(3) 4Cr5MoSiV1 (JIS SKD-61)

(4) 9Cr18MoV

(5) HPT

**Bimetallic Alloy Materials:**

1) Fe-based alloy

2) Ni-based alloy / Deloro alloy

3) Co-based alloy

4) NiCo-based alloy

5) Tungsten carbide / Wolfram carbide

**Technologies Used:**

Heat treatment, High-frequency quenching, Nitriding treatment, Hard-chrome electroplating, Bimetallic alloy welding, Bimetallic alloy centrifugal casting

**Technical Parameters:**

Nitrided layer depth: 0.5–0.8mm

Nitrided hardness: 900–1000HV

Nitrided brittleness: Less than Grade 1

Surface roughness: Ra 0.4

Screw straightness: 0.015mm

Hard-chrome plating hardness after nitriding: ≥ 950HV

Chrome-plating layer depth: 0.025–0.085mm

Bimetallic layer depth: 3mm

As an experienced manufacturer, we focus on quality, innovation, and customer satisfaction. Our products are widely used in injection molding machines and are known for their durability, precision, and performance. With years of experience in the industry, we ensure that every product meets international standards and is tailored to meet your specific needs. Whether you need a standard model or a fully customized solution, we are here to support you with reliable service and technical expertise.